The New Downee Catalogue is Here – Explore It Today!

WHY INDUSTRIAL SWING GATES REQUIRE SPECIALISED AUTOMATION SOLUTIONS

March 3, 2025

Industrial sites require secure, reliable, and high-performing automation solutions to manage controlled access. While sliding gates are often the default choice for industrial facilities, swing gates remain a critical solution in many environments. However, automating an industrial swing gate presents unique challenges that require specialised motors, control systems, and safety features to ensure seamless and secure operation.

In this article, we explore why industrial swing gates demand purpose-built automation and how selecting the DA6000 Swing Gate Operator can enhance efficiency, safety, and long-term reliability.

1. When is a swing gate the right choice?

Industrial facilities often choose sliding gates for high-traffic entry points, but in cases, a swing gate can be the more practical and effective solution;

– Limited space for a sliding track: Swing gates do not require extended lateral clearance, making them suitable for sites with space constraints or uneven ground.

– Challenging site conditions: Uneven terrain, slopes, or areas where a sliding track would be impractical benefit from a well automated swing gate system.

– High-security applications: Swing gates offer dual-leaf configurations for secure, controlled access, making them a strong choice for defence facilities, industrial zones, and restricted areas.

– Heavy vehicle access: When wide entry points are needed, double-leaf swing gates allow seamless entry without requiring extensive track systems.

– Heritage or architectural considerations: In some instances, swing gates are preferred for aesthetic or regulatory reasons.

While swing gates provide distinct advantages in these environments, they must be equipped with the right automation and hardware systems to ensure performance and longevity.

2. The unique demands of industrial swing gate automation

Unlike sliding gates, swing gates operate on pivot points rather than tracks, creating distinct challenges that require specialised automation and hardware solutions.

– Weight and load-bearing demands: Industrial swing gates are often wider and heavier than standard gates, requiring high-torque motors capable of handling substantial force.

– Wind resistance and environmental factors: Swing gates are directly impacted by wind loads, requiring advanced force control and robust mechanical design to maintain stability.

– Duty cycle and operational frequency: Industrial applications demand high-cycle automation solutions, ensuring the motor can perform consistently without overheating or excessive wear.

– Safety and compliance: Swing gates must be equipped with proper safety mechanisms, such as photocells, pressure sensors, and force limitation technology, to prevent risks associated with the gate’s swinging motion.

Standard automation systems often fail to accommodate these factors, leading to premature wear, erratic operation, or potential safety hazards.

3. The key features of a purpose built swing gate operator

A true industrial swing gate operator must be designed to withstand high-frequency operation, environmental exposure, and safety requirements.

– High-torque motor design: Ensures smooth operation under heavy loads without excessive strain.

– Soft-start and slow-stop functionality: Minimises impact on hinges and structural components, preventing excessive wear over time.

– Heavy-duty, weather-resistant casing: Protects the motor from dust, moisture, and temperature extremes, ensuring reliability in industrial environments.

– Advanced access control integration: Compatible with RFID, keypads, remote systems, and security networks for seamless control.

– Comprehensive safety mechanisms: Includes photocells and emergency stop functions to meet growing industry standards.

Selecting the correct motor ensures long-term performance, minimises downtime, and reduces maintenance costs.

4. The Downee approach: Engineered for industrial performance

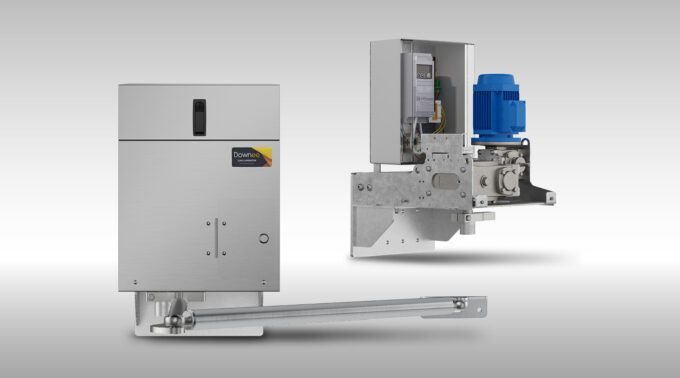

At Downee, we recognise that industrial automation requires more than just power—it demands precision and reliability. Our DA6000 Swing Gate Operator is designed specifically for industrial applications, providing:

– Heavy-duty performance: Designed to handle intensive daily operation with ease, with a 100% intensive duty cycle rating.

– Built for industrial strength: High-torque motor designed for heavy-duty applications up to 6m.

– Precision control: Smooth, controlled operation with soft start/stop technology to reduce wear.

– Australian made: Locally developed and backed by 96 years of experience for leading performance.

– Designed for Australian conditions: With a 316 Stainless steel cover and weather resistant design, the DA6000 is built to withstand the harshest conditions.

– Seamless integration: Works with a wide range of access control and security systems.

– Trade-focused support: Backed by local expertise, ensuring seamless installation and ongoing servicing support.

Every industrial site is different, which is why we work closely with installers, security professionals, and facility managers to ensure the right automation solution is specified for each project.

The right automation makes the difference

Selecting the correct automation solution for an industrial swing gate is about more than just installing a motor—it requires a consideration of gate size, environmental factors, usage frequency, and safety compliance. A complex process which Downee’s technical experts can simplify.

Choosing the right solution prevents operational failures, extends the lifespan of the gate, and enhances security. Industrial swing gates require purpose-built automation designed for heavy loads, high duty cycles, and challenging environments. Working with an expert supplier ensures every installation is equipped for long-term performance.

For specialist advice on industrial gate automation, Downee’s team of experts is here to help. For more information on the DA600 Swing Gate Operator download the brochure below.